“That’s the way we have always done it.”

That is a very scary phrase. It typically implies that you are not changing or looking to improve. It can also imply that you have done it for so long, you may be getting lax in some areas and not realize it.

When it comes to a dairy’s clean-in-place (CIP) routine and products, “That’s the way we have always done it” could be costing you milk quality.

With money at stake, let us take a refresher on the CIP basics.

Milking equipment cleanliness and proper functionality play a big role in improving or maintaining a low standard plate count (SPC) or bacteria count. Milk “soils” which challenge milking system cleaning include proteins, micro-organisms, minerals, sugars and fatty acids. It is believed that today’s high-producing cows create six different types of fatty acids, causing additional cleaning challenges. If done properly, the CIP process attacks each of these challenge areas. The process generally consists of four phases: pre-rinse, cleaning (single- or two-step), acid and sanitizing.

The pre-rinse phase is arguably the most important phase during the CIP process, as this phase should remove 90% to 95% of milk’s soils. To effectively remove contaminants, we recommend flushing the system with 110ºF to 120ºF water and keep flushing until the rinse water discharge is clear. It is extremely important that you do not re-circulate this rinse water. If you recirculate the water, you are just re-introducing proteins, soils and bacteria into your system, which is counterproductive.

Many cleaning challenges we find on farms are traced back to inadequate pre-rinse procedures. When the pre-rinse is inadequate, some farms attempt to make up by using a higher concentration of chemicals in the cleaning, acid and sanitizing steps, or do not change anything and live with the high bacteria counts. Using higher concentrations costs the producer more than just money; there’s potential for increased groundwater contamination and possible system damage, including discoloration of stainless steel and damage to plastic and rubber components.

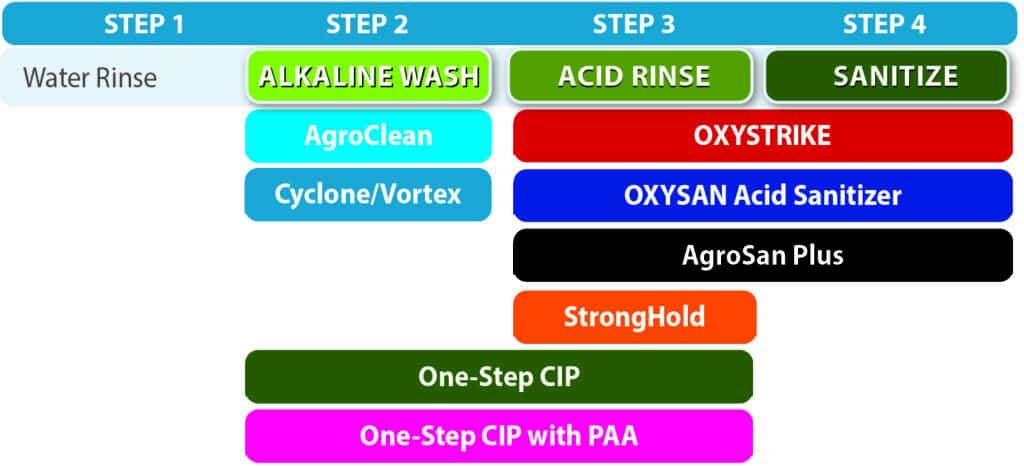

The cleaning phase, which follows the pre-rinse phase, can be either a single-step or two-step process, depending on the detergents selected. Cleaners carry out four basic functions to keep soils in suspension until removal: penetrate soil, lift soil from surface, break up soil into small particles and saponify (decompose) fatty acids.

Not all of these detergents are created equal, and that is intentional, as selecting the proper detergent is a science. The correct detergent and proper usage ratio will depend on factors relevant to the dairy, such as water hardness, iron content, water use, soil type, soil load and size and type of equipment.

The main constant for the detergents is that, in order to be effective, detergents need the correct wash water temperature throughout the wash cycle. Water at the end of the cycle must be a minimum of 120ºF; on most farms, that means starting temperatures need to be approximately 160ºF.

If these temperatures cannot be achieved, producers need to use products specifically designed for lower water temperatures. These lower water temperature detergents are often marketed as

Because detergents (soaps) and chlorine typically leave behind mineral deposits, the acid phase follows the cleaning phase. Acid circulation in CIP procedures is included to remove encrusted protein and salts from the surfaces. Acids are most effective at removing detergents and chlorine residuals. Add just enough acid to warm water (100ºF to 120ºF) to get a pH of 3 to 4. If the acid rinse is 68ºF or lower, use a non-foaming acid. If silicates are present in the dairy’s water, do not let the pH drop below 5.

The final step is the sanitizing phase. To comply with Pasteurized Milk Ordinance (PMO) regulations, circulate an EPA-registered sanitizing solution, according to the manufacturer’s guidelines, no more than 30 minutes prior to the next milking shift. If producers follow the recommended sanitizing phase, 99.9% of bacteria should be eliminated.

It should be noted that there are many different chemicals which can be used as a sanitizer. Each of them have their own benefits and should be looked at accordingly. Some may or may not be compatible with your system, which could lead to corrosion.

Those are the basic steps for CIP. Now chemistry has evolved over time, which is a good thing. Some companies have been able to create products that combine the cleaning and acid phases, and others have a product that can combine the acid and sanitizing phases. When used properly, these products can help reduce time, overall chemical use, energy and water, as some of these products are no-rinse solutions.

Additionally, as dairies start installing robots, check with the manufacturer for what types of products will work with the robot. Some of these robots do not work well with chlorine and could damage your investment.

Some companies have also developed “shock treatment” additives for your system. While some of these do work, they are not meant to be used as an alternative to a proper CIP cleaning procedure. I repeat, do not rely on shock treatments, as they only delay the inevitable. They are good for the occasional treatment but are not meant to be a final solution to soil buildup. A consistent CIP process after milking is the best way to ensure clean lines and a step toward those milk premiums.

It doesn’t matter if you have a typical milking system or robots; over time, protein, fat and mineral buildups occur in pipelines. Proper cleaning procedures should reduce or eliminate buildup. Strive to clean the system with a consistent, cost-effective and environmentally friendly procedure.

In summary, remember that several factors impact cleaning – time, temperature, chemicals/concentration, mechanical effect, water quality, soil being removed, type of surface being cleaned, cleaning method and people. To maximize cleaning effectiveness, make sure each factor is performing at its optimum.

Just like all the tasks on your farm, it takes teamwork to maintain an efficient and properly functioning milking system that fosters quality milk production. I recommend working with your milk cooperative field representative, veterinarian, financial adviser, equipment service technician and chemical company representative to set standard operating procedures for the dairy’s employees and monitor the results. The team should meet (at least) once a quarter to review results and progress and develop and implement any necessary new action steps to improve quality milk production.