Not long ago, my colleague Chip and I visited a 600-cow dairy farm in Texas that was looking for some help. They were claimed to be struggling with these things:

What could be the underlying issues? We rolled up our sleeves to find out.

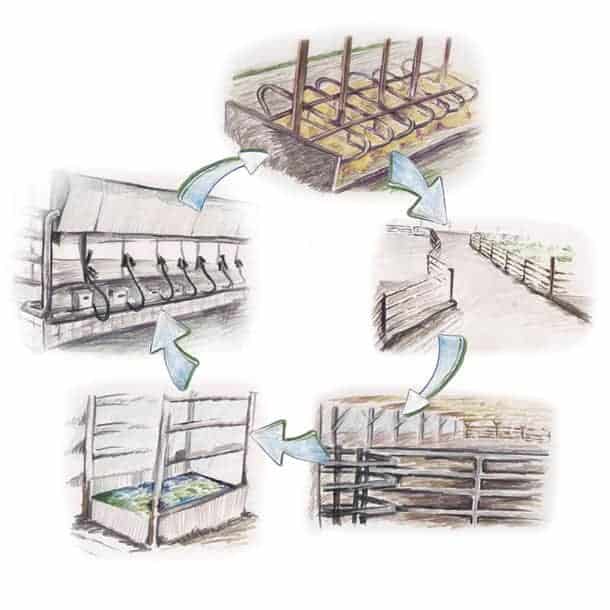

Being hoof trimmers by trade, the hoof issue was the first thing we examined. We visited the footbath first. It was being used frequently and at the proper concentration levels with a programmed footbath dosing system running HEALMAX® Footbath Concentrate. After footbath inspection, we asked the herdsman to take us to the stalls and walk us through the entire milking process so we could gain a clearer picture of the operation. The herd was about to go in for its second milking, giving us a perfect view of the operation.

In the barn, the stalls were very clean. The floor was only a couple of years old and still in great shape. We followed the cows’ path from the barn, then down a path outside and into the holding pen. Observing the outside path, we noticed the herd was walking on the edges of the lane instead of spreading out over the path; some cows were walking with a gait. We also noticed that just beyond the path, there were a few knocked-over trees and brush piles. In talking with the manager, we learned a nasty rainstorm had blown down the trees and caused some small-scale floods on the farm. We also learned he and another employee trimmed in-house and, if they noticed foot issues, their plan of action was an increase in footbath days.

We immediately recommended he bring in an outside hoof trimmer (not us, our days of trimming are for younger folks) to take a look at the herd due to the gaits we noticed. Then we looked closer at the path and realized the camber (sloped angle of the path) appeared to be off. Now cows love walking on flat surfaces, but when outside, a path must have a slight camber (less than 8 degrees) for water runoff. Anything more than that causes the cow to be uncomfortable walking. Her reaction will be to slow down and try to find the flattest part on which to walk. Due to the storm, it appeared the path was eroded, and the camber was 13 degrees.

The herdsman said he noticed the cows all started walking down the same side of the path each time they came in the pen, but he thought it was just a weird habit they developed. This habit ended up being developed because they weren’t comfortable with the angled surface which, in turn, forced the herd to slow down movement to the pen. Angled surfaces also play a role in hoof health. If a surface is uneven or rough, it can cause parts of the hoof to become uneven, creating pressure points which can lead to an array of hoof issues. We recommended fixing the path as soon as possible and to bring in an outside hoof trimmer to inspect the herd.

Once the herd reached the pen, they all started to settle in. This farm had a round pen with an electric push-button back gate. An ideal pen gives cows about a yard between each other, and this pen checked that box. (If a pen is tight, the cows get uncomfortable and uneasy.)

As the herd was allowed into the parlor, down the alley towards the footbath, the herdsman operated the push-button back gate. The gate was moving about a yard every five seconds but would only advance with another push of the button. This is something we recommend on larger farms, as a turn-on switch that automatically moves at a linear pace of 1 yard every five seconds has the potential to physically touch the cows in the back of the herd and not stop. The push button is preferred so you avoid the back gate from physically hitting and potentially harming the cows. This farm’s pen was set up the exact way we would have set it up, and it moved on to the alley toward the footbath.

The herd as a whole was slow to move into the building from the pen, even though the lead cow moved in pretty quickly, and the alley was roughly 5 yards wide. When we made our way into the building, we noticed how much darker the entrance was compared to being outside. Cows, by nature, do not like the dark. Going from a bright location (such as outside) to a dark indoor area makes them hesitant. I recommended they switch to an LED bulb to brighten the area and ease the transition.

All of a sudden, there was a traffic jam in the alley, right at the footbath. The 5-yard-wide alley quickly funneled down to a single-yard width for the footbath. Cows had their heads up and didn’t want to go into the bath, halting them from entering the parlor. When the cow did go into the bath, some of the larger ones that had trouble fitting into the footbath alley slowed down and soiled the bath. Others would sprint just to get through it. This set-up clearly was not working for the herd. Our recommendations were to change the set-up.

After a few frustrating moments at the footbath, the cows made it to the parlor, which was about 20 years old. We noticed that some went right into the parlor to get milked, while the bigger cows moved slowly and needed extra encouragement to get into the stall. We stressed to the herdsman that cow comfort is extremely important in all areas of the farm. If the parlor stalls are uncomfortable, the cow will be slow to go into the stall; that stress interferes with milk letdown. He needs to make sure the entire process for the cow is a positive experience.

We sat down with the owner and head herdsman to share our conclusions:

1. Hoof issues: Hoof issues were most likely caused by the uneven path and poor flow through the footbath. The increased soiling in the bath can easily cause a footbath additive to lose its efficacy; further, cows sprinting through the bath most likely were not seeing proper absorption of the additive. The overall increase in time spent milking the herd was due to a lack of cow comfort. If the cows were comfortable, they would move at a solid pace from Point A to Point B. Once they start becoming uncomfortable, they slow down.

2. Decreased milk production and milking efficiency: We attributed the production decrease to a milk letdown interference. Cows were stressed before they entered the parlor. Combine that with a parlor stall designed 15 years ago for a smaller-sized cow, it’s no wonder the herd reduced production. We spoke about how important it was to make sure the cow was comfortable during the entire process from the stall to the parlor.

Our recommendation: Fixing the path, the lighting and the alley by the footbath should increase the pace/speed it takes the cows to get to the parlor.

About a month later, I came back to the farm at the owner’s request and noticed some changes. The dairy team changed the things within their ability, though bigger changes to the parlor will occur at a later point in time.

They fixed the path between the stall and pens, and now it had a camber of 5 degrees. The cows were now walking three to four cows wide down the path into the pen, at a nice pace, and the gait appeared to be gone. The parlor building switched to LED bulbs throughout the building, which brightened the place right up, and the herd exited the pen without issue into the alley.

Near the footbath, the traffic jam was no more. They changed the way the alley funneled so it was a more gradual decrease in width. The flow through the footbath was smooth, and the herdsman said soil load in the bath decreased. A call to the hoof trimmer was helpful in identifying uneven hooves and some underlying foot issues.

With all of these tweaks, the manager reported that the time it took to milk the herd dropped back down to 2.5 hours (saving him an hour) and milk production had increased. In the end, cows are happier, healthier and more productive, and the dairy manager has a few less headaches.