Dairy producers today know the importance of using footbath additives correctly to achieve best results from their hoof health program. Here is a sample program using the HoofMax additive from AgroChem for copper and zinc sulfate footbaths for best results .

Measurements and simple math calculations are all that is needed. Once you know your footbath capacity, you can determine the proper amounts of copper sulfate and HoofMax needed to obtain optimum benefits.

Multiply the length, width, and height of the footbath in inches then divide by 231:

L x W x H ÷ 231 = footbath capacity in gallons

The amount of copper sulfate needed depends on your current Cu usage and your footbath size. A good rule of thumb is to use from 50-60% of the current amount of copper. The chart below will help:

Footbath size <50 gal, 10-12 lb Cu

Footbath size 50 gal, 10-15 lb Cu

Footbath size >50 gal, Add additional 2 – 2.5 lbs copper for every 10 gallons above 50 gal capacity

Footbath size <50 gal, 12-15 lb Cu

Footbath size 50 gal, 15-25 lb Cu

Footbath size >50 gal, Add additional 2.5 – 5 lbs copper for every 10 gallons above 50 gal capacity

The amount of HoofMax to use for best results is determined by multiplying 12 oz HoofMax by every 100 cow passes:

12 oz HoofMax x Every 100 cow passes = Total ounces of HoofMax needed

The maximum cow passes for 50 gallons of water is 500; the maximum cow passes for 100 gallons of water is 1000.

To illustrate, let’s say you have 300 cows and are currently using 20 lbs of copper per bath that measures 32″ wide by 66″ long by 5″ in height.

32 x 66 x 5 ÷ 231 = 45.7 gallon footbath capacity

According to the chart above, the amount of copper sulfate needed for a 45.7 gallon capacity footbath for your farm is between 10 and 12 lbs. Next, take the number of cow passes (300) and calculate the amount of HoofMax needed by multiplying 12oz by 3 (1 for every 100 cows to pass).

12oz x 3 = 36oz of HoofMax

For maximum hoof hardness and minimum hoof rot, this protocol should be run at least 3 to 4 consecutive days per week if it is the only hoof bath product being used.

Hoofmax, the original additive for footbaths based on copper or zinc sulfate, not only allows producers to reduce their copper sulfate usage, but it also reduces the overall cost of their footbath program. Even when the bath is heavily loaded with manure and urine, HoofMax optimizes footbath chemistry to significantly increase the potency of copper or zinc sulfate and enables the copper to continue working. This allows you to use less copper and change the bath less frequently.

Contact your dealer or an AgroChem representative for help in determining copper availability for each farm’s individual protocol.

Hairy Heel Wart, (Digital Dermatitis), a condition well-known to dairy producers, is quickly becoming an issue for beef producers as well. According to Dr. Jan Shearer, ISU Extension Veterinarian at Iowa State University, there has been an increase in incidence of DD, causing a significant problem for the beef industry.

Digital Dermatitis causes heel erosion and eats away at the skin, causing very painful lesions most commonly found in the plantar interdigital cleft. Once a herd is infected, recurrence is common, which has prompted many feedlot owners to seek ways to manage DD. The answer to this emerging lameness issue for beef producers is to establish effective and economical treatment and control strategies, such as:

Topical products have been shown to be effective against hairy heel wart. Products like HealMax,available in a spray or foam formulation, provide feedlot operators with a formaldehyde-free, heavy metal-free option for digital dermatitis.

Footbaths containing copper sulfate are widely used in the dairy industry, and can be very effective in cleaning and disinfecting hooves. Feedlot owners are challenged to find the best location for a footbath so cattle cannot jump over or step around it. Copper loading on land can also be a problem. The use of footbath additives can help boost the potency of copper or zinc sulfate, remaining effective even after the bath is heavily loaded with manure and urine, and significantly reduce the amount of copper required for comparable results. HoofMax is a proven chemical additive shown to reduce copper sulfate use by up to 80 percent.

Want to know more about hoof care in feedlot? Contact Agrochem, Inc. today, or your hoof trimmer or veterinarian.

Source: Dr. Jan Shearer, Iowa State University https://beef.unl.edu/feedlotroundtable2012

Copper sulfate is a staple on many dairy operations these days, thanks to its efficacy in treating and preventing hoof health problems. Copper sulfate is bacteriostatic, binding to and neutralizing pathogens in organic matter that can cause digital dermatitis and other problems. After 150 cow passes or so, the used solution is traditionally mixed with manure waste and disposed by land application.

Unfortunately, copper sulfate accumulates quickly in soil. Researchers from the W.H. Miner Institutehave estimated that copper is applied to farm land at a rate of 4 lbs per acre approximately 18% of the time. The rate at which copper is removed from soil is much slower – only about 0.5 lbs/acre for typical grain and forage crops. Without careful management, dairy farmers may exceed their maximum soil copper loading in as few as five years, resulting in toxicity to soil microbes and crops.

Regulators in several states are now pressuring dairy producers to reduce or eliminate the use of copper sulfate in footbaths. Strategies for reducing copper loading on land include:

Once copper sulfate reaches the toxic threshold in soil, the problem cannot be reversed. Careful management at every stage, from footbath preparation to manure disposal, can go a long way in reducing copper loading on land. See your professional hoof trimmer for more information on managing copper sulfate in your dairy operation.

Source: Epperson, Bill and Midla, Lowell. Copper Sulfate for Footbaths – Issues and Alternatives. Tri-State Dairy Nutrition Conference, April 24-25, 2007.

The multiple challenges of fighting the “good fight” against infectious hoof disease can make it tough to gauge the real extent of lameness in your dairy herd. They can also inadvertently lead to some cows being retreated for the same stubborn hoof lesion at every trimming, while others who may need it go untreated.

Noted veterinary researcher Dr. Nigel Cook of the University of Wisconsin–Madison has authored a new guide that more effectively systematizes lameness management in large and small dairy herds. Calling current statistics “deeply flawed,” Cook aims for a truer picture of the extent—and causes—of lameness within an operation, outlining a defined plan for permanently reducing lameness levels over time.

Several years in the making, Cook’s system starts with locomotion scoring at specific intervals, based on herd size, and monitors the proportion of cows with abnormal locomotion scores over time. Detailed recordkeeping throughout ensures that all cows are accurately assessed, while also identifying the prevailing causes of lameness.

Among the primary trigger factors for lameness, Cook’s study calls digital dermatitis (hairy heel wart) “by far the most common infectious lesion found in dairy herds.”

When you’re fighting digital dermatitis and other infectious hoof diseases, manage it by implementing a regular footbath program using copper or zinc sulfate footbaths with HoofMax® by AgroChem, Inc. Producers use HoofMax to increase copper/zinc potency which promotes hoof hardness, and helps fight digital dermatitis and other diseases.

If you’re looking to limit the amount of formaldehyde being used, producers may want to consider using a HealMax®, as well. This formaldehyde-free solution helps reduce the incidence, severity, duration and recurrence of digital dermatitis in lactating dairy cows.

For more information on protecting herd hoof health, consult your hoof trimmer or veterinarian.

SOURCE: Nigel B. Cook MRCVS, “A Guide to Investigating a Herd Lameness Problem,” University of Wisconsin-Madison School of Veterinary Medicine.

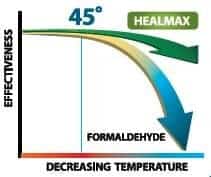

With cold weather right around the corner, it’s important to make sure your hoof health regimen is ready for the months ahead. Winter conditions present several challenges. Freezing temperatures can prevent footbath set-up, and many anti-microbials are negatively affected by lower temperatures. Bacteria that cause hairy heel wart, on the other hand, are not as affected, and can remain active throughout the winter. Formaldehyde, commonly used to control bacteria and maintain hoof health in warmer temperatures, decreases in effectiveness at temperatures below 45 degrees Fahrenheit.

Some dairy producers in the Dakotas and elsewhere in the Great Plains states are finding winter-weather success with topical antiseptics like HealMax. Available as a spray, foam or footbath concentrate, HealMax delivers results year ‘round, without the disadvantages of formaldehyde.

Lameness is one of the most devastating diseases impacting animal welfare and profitability in U.S. dairy operations. Economic losses commonly associated with lameness include treatment costs, reduced milk production, decreased reproductive performance, and premature culling. Some cited costs include:

Preventative hoof care can go a long way in reducing new lameness cases. Regular hoof trimming, copper sulfate footbaths with an additive like HoofMax, and prompt application of HealMax spray or foam to digital dermatitis lesions, can help reduce the incidence – and cost – of lameness in your herd.

Sources:

Shearer, JK and S. Van Amstel. Lameness in Dairy Cattle. Proceedings from 2000 Kentucky Dairy Conference, Lexington, KY, pp. 1-10, 2000.

Geni Wren. Investigating Dairy Lameness. Bovine Veterinarian, November 1, 2004.

Karl Burgi. Dairy Cattle Lameness Causes and Effects. Progressive Dairyman. February 6, 2007.

Peggy Coffeen. How much is lameness costing you? Agri-View, February 7, 2013.

Formaldehyde has long had a place in dairy footbath programs. It’s an effective hoof hardener, a powerful disinfectant, and costs less than copper and zinc sulfate. But formaldehyde has some serious drawbacks. Here are the top 5 reasons – in reverse order — why dairy producers should rethink the use of formaldehyde in their footbath programs:

• Reason #5: Formaldehyde is painful (for cows). The direct application of formaldehyde to raw lesions is extremely painful and stressful for the cow, and can lead to avoidance of the bath.

• Reason #4: Formaldehyde is irritating (to humans). Formaldehyde fumes irritate the eyes, nose, mouth and throat. Prolonged exposure may cause severe allergic reactions or loss of smell. Dairy producers must ensure facilities are well ventilated during formaldehyde application.

• Reason #3: Formaldehyde is flammable. Extreme care must be taken when using formaldehyde around any sort of open flame, including cigarettes.

• Reason #2: Formaldehyde loses effectiveness in hot or cold weather. Formaldehyde begins losing efficacy at temperatures below 45 degrees Fahrenheit, and evaporates quickly in hot weather.

• Reason #1: Formaldehyde is a potential carcinogen. The Occupational Safety and Health Organization (OSHA) calls formaldehyde “a cancer hazard.” The European Chemicals Agency (ECHA) calls formaldehyde as “a known animal carcinogen” and “suspected mutagen.” As a result, some communities in the U.S. are now calling for restrictions on the use of formaldehyde on farms.

Fortunately, products like HealMax by AgroChem, Inc. provide an economic means of safely managing hoof problems without heavy metals, harsh acids or formaldehyde. They contain a unique blend of germicides that remain effective in either hot or cold weather, with visible results in about one week. HealMax Footbath Concentrate should be used at a 2% dilution rate, with 300 cow passes per 50 gallons of water. There’s also a HealMax spray for spot treatments, and a foam formulation for treating the entire herd during feeding.

AgroChem, Inc. is proud to announce it has received EPA approvals for additional lines of its hay and feed preservatives. AgroChem’s HayFresh, HayFresh+Plus and ForageGaurd are now EPA compliant for use on corn, feed blends, haylage, and silage including wrapped high-moisture hay and feed blends.

“Receiving these EPA approvals significantly expands the number of uses for our products.” says Rob DeMarco, President of AgroChem, Inc. “Farms can use just one product for multiple feed types. They can be confident that the products are safe for their land and the environment while preserving the value of their hay and feed when in storage.”

AgroChem’s advanced line of chemical formulations used in dry forage preservation, prevent mold and preserve the freshness and color of forages.

The Footbath Dosing System from AgroChem, Inc. delivers a precise quantity of pre-mixed footbath concentration at the touch of a button, with no manual measuring or mixing required. The comprehensive, automated system ensures consistency, helps reduce costs, enhances accuracy, improves worker safety and improves overall hoof health.

The system can be programmed for use with two different products, each with its own pump, for use separately or in rotation. For example, producers who want results without formaldehyde may run HEALMAX®, while producers looking to reduce copper sulfate usage may run DURAHOOF.

Other benefits include:

According to Ben Collopy, a herdsman from Emerlings Dairy in Perry, NY, “The team loves the ease of the Footbath Dosing System. It keeps everyone safe and does a great job of improving hoof health.”

AgroChem, Inc. is a leading supplier of various chemical products for the dairy industry, including hoof care products, teat dips, parlor cleaning chemicals and hay and feed preservatives. For more information, call (518) 226-4850 or visit www.agrocheminc.com.

AgroChem Inc. is pleased to announce its recent hire of Ron Robinson, who will join the AgroChem team as Sales Manager. Robinson will focus on new business development opportunities.

“We are very excited to welcome Mr. Robinson to the AgroChem team. He offers many years of experience in the dairy industry,” said DeMarco. “His extensive knowledge of dairy chemicals and improving milk quality will be valuable to our customers and our team.”

Robinson has over 37 years of experience in the dairy industry in everything from dairy chemicals, milk processing and milk quality consulting. He will be instrumental in helping dairy producers to produce the best quality milk according to their unique dairy needs.

AgroChem, Inc. is a leading supplier of various hygiene products for the dairy industry, including hoof care products, teat dips, parlor cleaning chemicals and hay and feed preservatives. For more information, call (518) 226-4850 or visit www.agrocheminc.com